Can safety shoes cause bunions

How safety shoes cause bunions

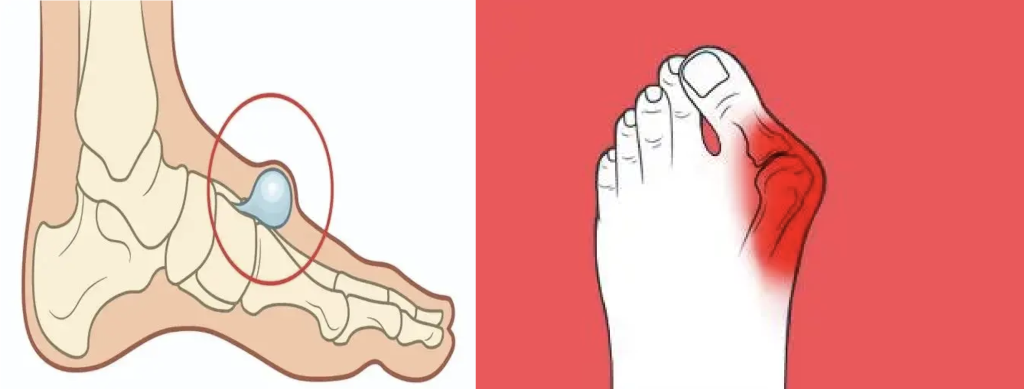

A bunion is a bony protrusion that forms at the big toe joint, which not only affects the appearance of the foot, but can also cause pain and discomfort. If the right safety shoes are not chosen correctly, it may cause the wearer to develop a bunion. Here are the reasons why safety shoes may cause bunions:

·Too narrow toe box

Safety shoes are usually designed to provide protection to the wearer, but some models of safety shoes have narrow toe boxes, especially safety shoes with a higher level of protection and steel toe safety shoes. If the toe box is too narrow, it will compress the toes, especially the big toe and the second toe next to it. Long-term compression will cause the big toe to tilt inward, and the joint part will protrude outward, gradually forming a bunion. Continuous pressure can cause arthritis, pain and local swelling. Narrow toe boxes will restrict the natural extension of the toes, affect gait, and further aggravate symptoms.

·Improperly fitting shoes

Improperly fitting safety shoes are also a major cause. If the shoes are too tight, the toes will be squeezed together, causing constant friction and pressure. If the shoes are too loose, the foot will slide inside the shoes, which will also cause unnecessary friction and movement of the toes, increasing the risk of bunions. Shoes that are too tight or too loose will cause uneven force on the foot when walking, increasing the pressure on the foot joints. Long-term improper foot posture can cause joint deformation, which will lead to bunions.

· Lack of adequate support and cushioning

Although some safety shoes provide good protection, they may not be sufficient in terms of support and cushioning. If the sole is too hard or the insole is not soft enough, the force point of the foot will be concentrated on the big toe joint, causing excessive pressure on the joint, especially when standing or walking for a long time. Lack of arch support will cause unbalanced force on the foot, leading to changes in foot structure, such as big toe valgus. Lack of cushioning will make the sole and joints more vulnerable to impact, increasing discomfort and the risk of injury.

How to prevent bunions caused by wearing safety shoes:

· Choose a loose toe box

Long-term compression of the toes is one of the important causes of bunions, so we should choose safety shoes with wider toes. Safety shoes with wide toes can ensure that the toes have enough room to move and the toes will not be squeezed together. When choosing safety shoes, make sure that all toes can move freely, especially the big toe is not compressed.

· Appropriate size

Make sure the shoe size is appropriate. Shoes that are too small can cause toes to be squeezed, while shoes that are too large may cause the foot to slide in the shoe, causing unnecessary friction and pressure. The shoe should leave about 1 cm of space in front of the foot. It is best to try it on in the afternoon, because the foot will swell slightly during this time of day, which can better reflect the actual size requirements.

· Breathability and material selection

Make sure the shoe material is breathable to prevent moisture and overheating of the feet, because a humid environment can easily cause friction and skin problems, which indirectly increases the pressure and discomfort of the feet. Choose safety shoes made of breathable materials, such as natural leather or mesh materials, which will help keep the feet dry.

· Regularly replace shoes

Safety shoes wear out faster due to frequent wear. Worn shoes may not provide enough support and comfort, increasing the pressure on the feet. Therefore, it is very important to replace worn shoes in time. Check the wear of the shoes every 6-12 months to ensure that the soles, toes and support parts are not excessively worn, and replace them in time if necessary.

·Choose according to the working environment

Different working environments have different requirements for safety shoes. For example, if you need to stand on hard ground for a long time, the cushioning performance and comfort of the shoes are particularly important; if the working environment is slippery or there is contact with chemicals, the anti-slip and corrosion resistance of the soles need special attention. Choose suitable functional shoes according to specific work needs, such as anti-slip, waterproof or acid and alkali resistant.